The Handy Paper Binding Machine - Perfect for All Your Binding Needs

Introduction:

Are you fed up with using traditional binding methods like sewing and stapling? Then, it's the perfect time for you to definitely spend money on a paper binding machine. Utilizing the advancement in technology, paper binding machines from FRONT are getting to be more sophisticated, user-friendly, and safer to utilize. We shall discuss the advantages of paper binding machine, how these are generally innovative, and just how they may be a very asset good every office.

Paper binding machines have several advantages over traditional binding methods. First, they've been versatile and will bind several types of documents, including reports, booklets, and manuals. You can easily adjust the FRONT machine settings to match your paper size, thickness, and type. Second, perfect binding machine produce professional-looking easy documents and neat to read through. Third, they are faster and much more efficient than traditional binding techniques, that could save you time and increase productivity.

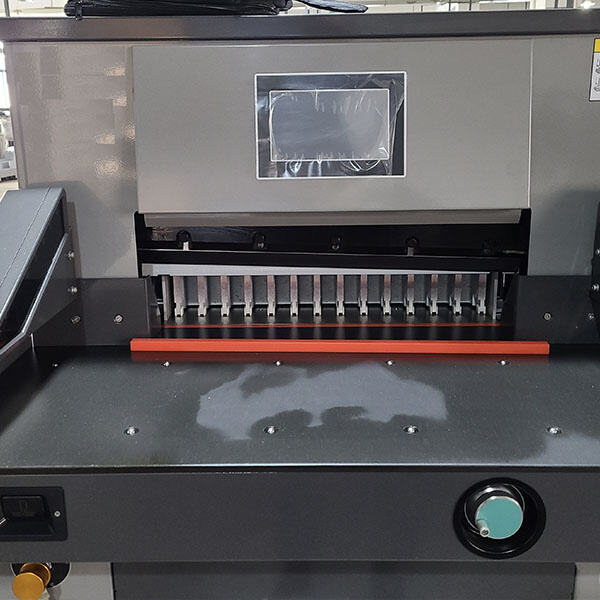

Due to the constant innovation the binding machine industry, modern paper binding machines have become more efficient and user-friendly. All of the new models with advanced features that make the binding process easier and safer. As an example, some FRONT models have digital displays that demonstrate you the binding progress, while other perfect book binding machine come with a built-in punch which eliminates the necessity of a separate punch machine.

Safety is an essential element and paper binding machines are not an exception. They have been made with safety features to cease accidents and injuries. For example, most FRONT machines come with a security sensor that stops the machine whenever your fingers are close to the punching area. Besides, the book binding tool is made of durable material that may withstand regular usage breaking down, which reduces the possibility of accidents caused by malfunctioning machines.

Using a paper binding machine is uncomplicated and easy. First, pick the type of binding style you need, either comb, coil, or wire binding. Second, adjust the FRONT machine settings to accommodate your paper size, thickness, and type. Third, align the papers and load them into the book binding machine's punch mechanism. Fourth, push the binding lever to bind the document, and you are also done.

company's production site encompasses area about 50,000 Paper binding machinemeters. It a highly-tech national company combines research, manufacturing sales. equipment technology expertly designed guarantee quality products. members team highly experienced possess professional capabilities, they take their job carefully integrity.

factory team customer-centric understands success organization based needs satisfaction clients. They Paper binding machine voice customers optimize production service meet expectations needs.

company adheres corporate policy "focus innovation, focus, trust" supporting corporate Paper binding machine "creating first-class quality, establishing status industry leader," company abides values "honesty respect, integrity, continuous progress." Through long history, company introduced numerous products, such laminators paper cutters. also offer folding machines, creasing machines, binding machines.

Zhejiang Daxiang Office Equipment Paper binding machine Ltd. top manufacturer post-printing processing equipment. was founded 2002 committed providing innovative, high-quality post-processing equipment printing industry. With impressive technical knowledge advanced production equipment efficient management team, stands a significant manufacturing entity US digital post-press well as office automation equipment industry.

Using a paper binding machine are intimidating when you yourself have never used one before. However, using this step-by-step guide, you're going to be a specialist in no time. First, assemble the machine according to FRONT's instructions. Second, select the binding design you prefer and adjust the machine's settings to suit your paper size, thickness, and type. Third, locate the punch load and mechanism the papers them correctly involved with it, aligning. Fourth, push the binding lever to bind the document. Lastly, remove the bound document from the perfect binding book machine and trim the excess binding material.

Paper binding machine manufacturers offer various packages with regards down seriously to service and quality. Some manufacturers offer warranties on the products, while others can offer customer support or repair services. Remember to research the producer's reputation before purchasing their product to ensure you obtain the product most quality readily useful and service feasible.

Paper binding machines made by FRONT have a wide array of requests, from small workplaces to large corporations. They can be familiar with bind documents, reports, manuals, and even materials marketing as brochures and flyers. Binding documents in-house is more cost-effective and much more convenient than outsourcing the job; it provides you more creative control your designs, and you will customize the binding styles to fit your brand aesthetic.