The HJ S2000P Smart Spray Gluer Binding Machine represents a departure from conventional gluing machines by incorporating cutting-edge features for enhanced performance, leveraging automatic gluing technology, PUR glue utilization, and an intelligent dust suction system. The overall design promotes cleanliness, reduces confetti accumulation, and enhances the efficiency and effectiveness of the binding process

The combination of automatic gluing technology, the use of spray glue dissolving canisters, PUR glue integration, and the dust suction system collectively leads to an enhancement in binding quality. This results in more reliable and professionally finished bound products.

The intelligent features incorporated into the HJ S2000P contribute to increased efficiency and productivity during the bookbinding process. The combination of automatic functions streamlines operations and improves overall throughput.The machine is designed with user-friendliness in mind, offering intuitive controls and features that simplify the binding process. This ensures a positive user experience and facilitates efficient machine operation.

Specifications

| Item Model | S2000P |

| Length(mm) | 460 |

| Thickness(mm) | 60 |

| Speed(books/h) | 200-300 |

| Milling cutter | Slotting knife |

| Vacuum | Dust suction fan |

| Mute air pump | × |

| Power | 220V, 50HZ2. 8kw |

| Machine weight | about320KGS |

| Machine dimension(mm) | 1500*650*1040 |

Competitive Advantage:

1.Automatic Gluing

The machine is equipped with advanced automatic gluing technology, streamlining the gluing process for precise and consistent application. This feature contributes to achieving a more secure and perfectly bound product

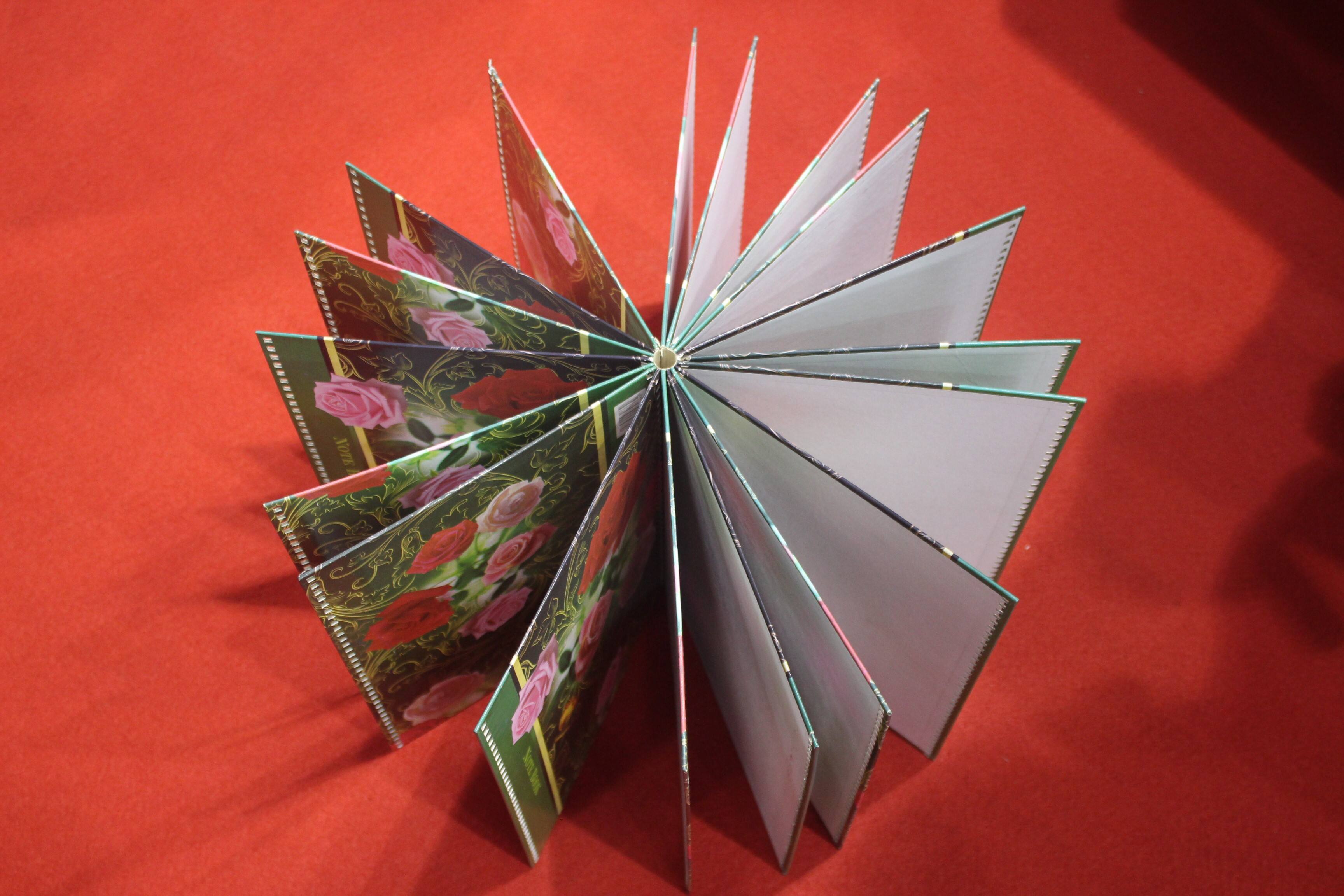

2.Spray Glue Dissolving Canisters

Utilizes spray glue dissolving canisters, a technology that optimizes the glue application process. This innovative approach ensures an even distribution of glue along the spine, enhancing the overall binding strength and quality

3.PUR Glue Integration

Incorporates Polyurethane Reactive (PUR) glue, a high-performance glue known for its exceptional bonding strength and flexibility. The use of PUR glue contributes to achieving a more durable and robust binding.

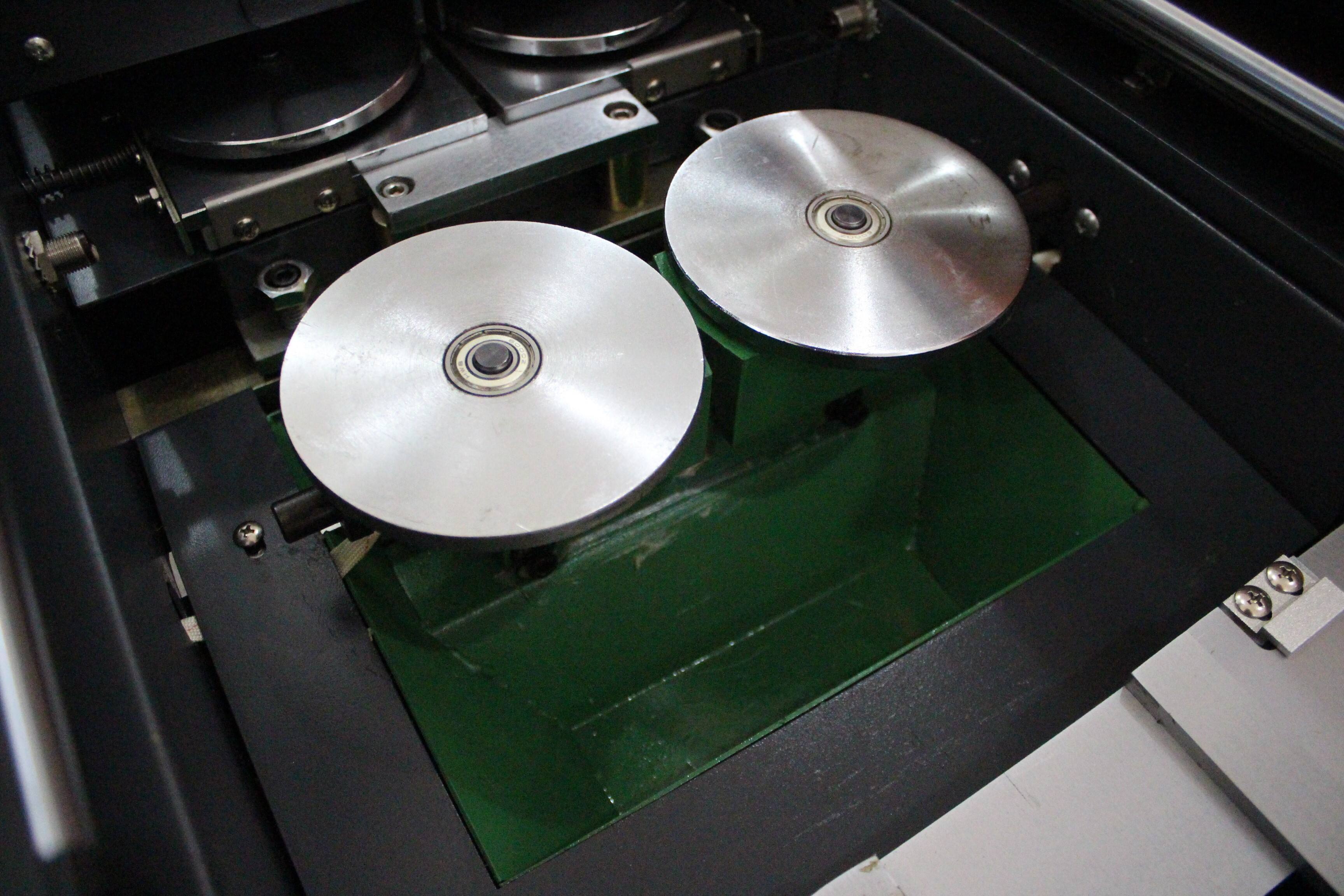

4.High-Power Milling Back with Tungsten Steel Sun Knives and sophisticated Milling and Notching Device

Features a high-power milling back equipped with 22 double-layer tungsten steel sun knives. This configuration enhances the precision of the milling process, contributing to the overall quality of the binding.

Incorporates a sophisticated milling and notching device for spine preparation. This ensures a precise and well-prepared spine, promoting a strong and durable binding result.

5.Reduction of Confetti Accumulation

The implementation of double wind page independent dust suction motors significantly reduces the accumulation of paper confetti during the binding process. This reduction not only ensures a cleaner working environment but also positively impacts the longevity and efficiency of the machine.

6.Tidy Overall Design

The machine boasts a well-organized and tidy overall design, enhancing its professional appearance. This design not only contributes to aesthetics but also facilitates ease of use and maintenance for operators.