The launch of HJ C90 intelligent gluing machine is for those who need gluing quality but have no operating experience, the binding quality can be realized through simple operation, with environmentally friendly hot melt adhesive, it is undoubtedly your office binding small assistant. This gluing machine adopts frequency conversion speed control technology, intelligent control, according to the thickness of the glued books, automatically adjust the machine running speed, presenting perfect binding effect. And the use of PLC integrated module control circuit design, more stable and reliable, the average service life will be lengthened, the emergency can also be intelligent power off to protect the operator.

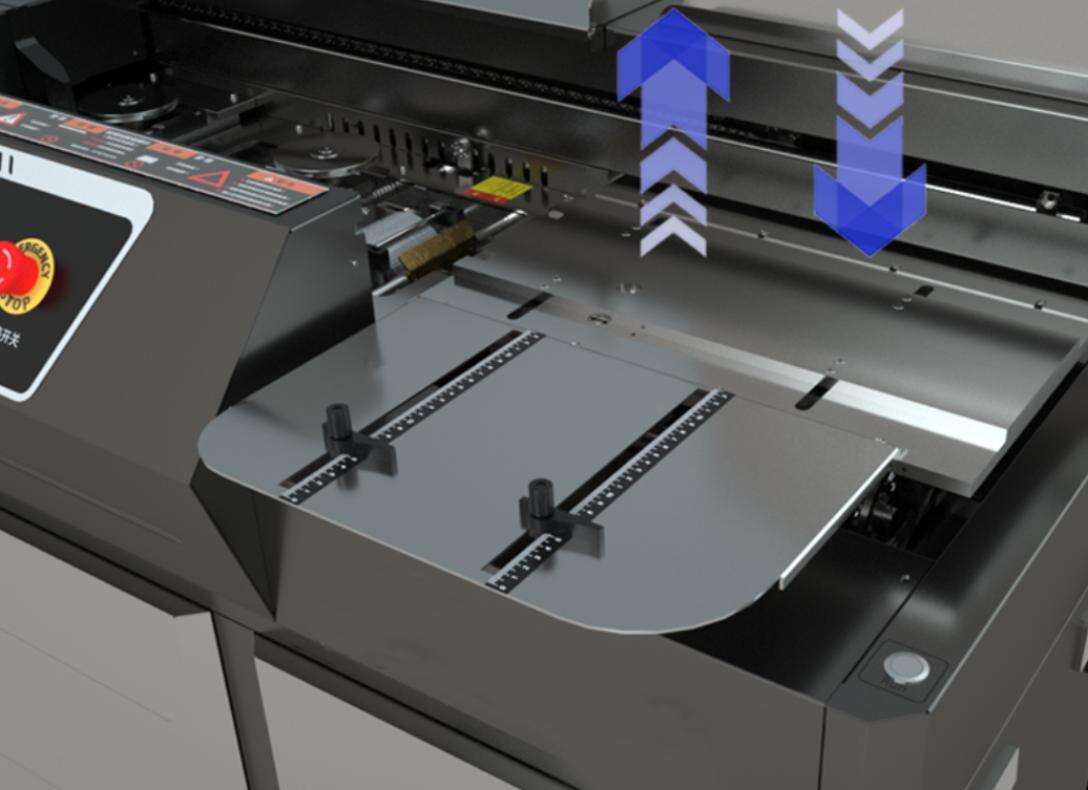

This intelligent gluing machine adopts the overall heavy-duty frame structure design, all cast aluminum running car, machine performance is stable and reliable. It also increases the cast aluminum gluing groove, double glue wheel gluing structure bottom glue more evenly, suitable for batch gluing. The machine adopts double wind page pipeline system to ensure less paper dust and improve the quality of binding. The clamping table of the machine can automatically lift and automatically measure the thickness, the touch screen can display the thickness, the clamping table will be based on the thickness of the book, automatically adjust the height of the lift, to apply to the book into the line of the desired effect, without manual adjustment.

Specifications

| Item Model | C90 |

| Operation mode | Single |

| Length(mm) | 460 |

| Thickness(mm) | 60 |

| Speed(books/h) | 350-450 |

| Milling cutter | Suncutter+small milling cutter |

| Display | 7''touch screen |

| Power | 220V, 50HZ3. 5kw |

| Machine weight | about330KGS |

| Machine dimension(mm) | 1700*600*1020 |

Competitive Advantage:

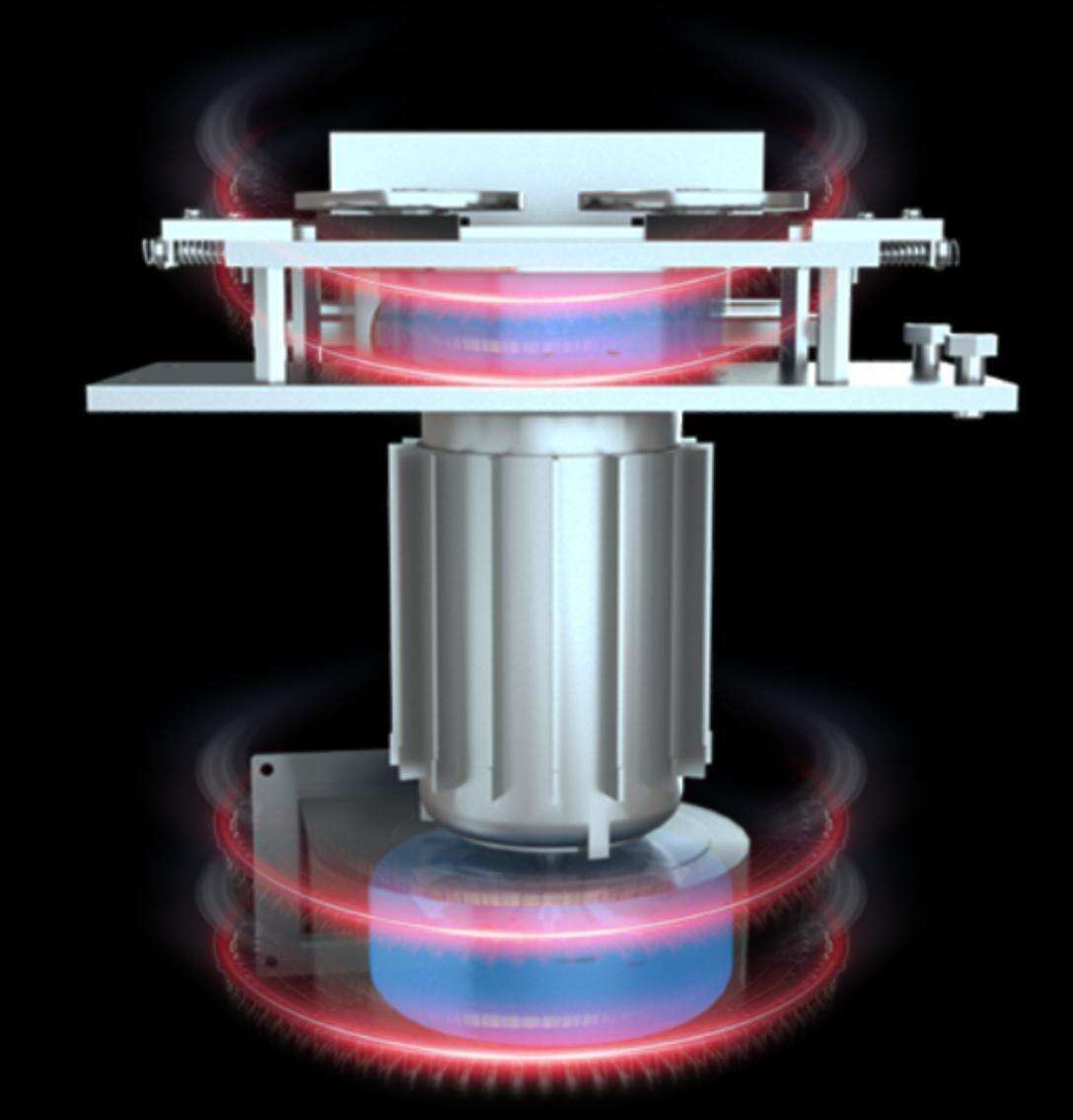

1.Variable frequency and variable speed control

The integration of frequency conversion and variable speed control technologies in gluing processes not only ensures perfect and consistent adhesive application but also positions companies at the forefront of industry standards and innovation. These technologies provide the flexibility, precision, and efficiency needed to meet the diverse and evolving requirements of modern manufacturing and packaging operations.

2.Side glue function and finishing glue

Automating the spine side gluing process in bookbinding or similar applications can enhance efficiency and ensure a more perfect gluing effect. It not only improves efficiency but also ensures a consistently high-quality gluing effect. Regularly update your processes based on feedback and technological advancements to stay at the forefront of automation in bookbinding or similar industries.

Effectively solve the problem of book adhesive,avoid glue sticking to the book holder

Minimizing the issue of adhesive sticking to the book holder or any other unintended surfaces during the bookbinding process is crucial for achieving a clean and efficient production.

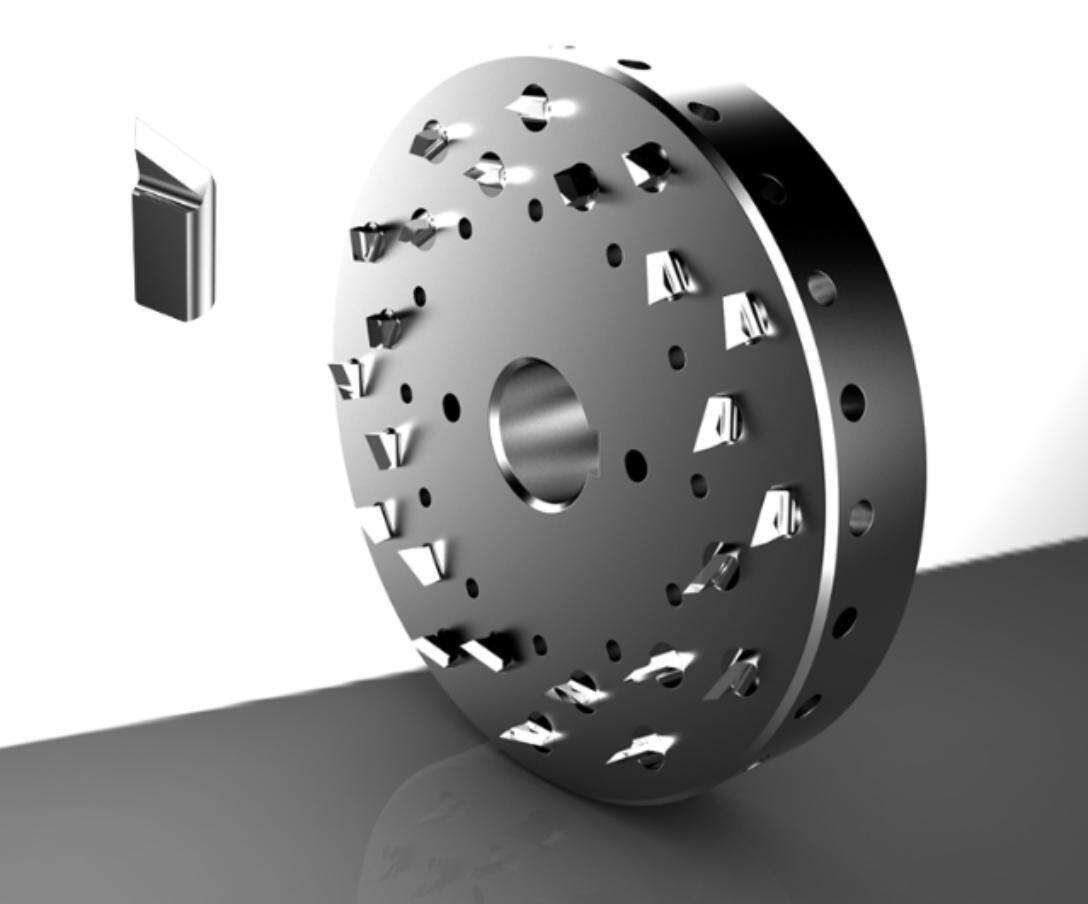

3.30 teeth alloy milling cutter

A 30-teeth alloy milling cutter is a tool designed for precision milling in various applications, particularly in the context of binding machines where it plays a crucial role in preparing the spine for adhesive binding.the 30-teeth alloy milling cutter combines strength, durability, and precision to create a tool that enhances the milling process in binding machines. Its even slotted and milled back, along with increased bonding force, contribute to achieving high-quality and durable adhesive bindings

4.Industrial linear guideway structure

Linear guideways, commonly used in industrial machinery, play a crucial role in ensuring smooth and precise movement of machine components. A well-designed linear guideway structure contributes to reduced friction, minimized noise, and enhanced overall performance. Here are key aspects of an industrial linear guideway structure that can help achieve smooth machine operation and minimize sound

By paying attention to these aspects in the design and implementation of industrial linear guideways, you can achieve a smooth machine operation with minimal noise. Regular maintenance and proper care of the linear guideway components are also essential for prolonged performance and reduced wear over time

5.Double fan suction motor

Good vacuum cleaning effect,less paper scraps,and improvement of binding quality

By incorporating these features into the design and operation of a double fan suction motor in a binding machine, you can achieve a highly effective vacuum cleaning effect, minimize paper scraps, and enhance overall binding quality. Regular monitoring and maintenance are key to sustaining these benefits over time.

6.Clamping structure

Vertical lifting gear,rack clamping surface structure,good shaping effect of adhesive bound books

Integrate a rack clamping surface structure to enhance stability and precision during the clamping process. The rack system allows for accurate positioning and alignment of the book, minimizing the risk of misalignment and improving the overall shaping effect.